DESIGN. BUILD. TEST. FLY. REPEAT.

DESIGN. BUILD. TEST. FLY. REPEAT.

CAPABILITIES

CAPABILITIES

“Successfully combining creative design with sound engineering principles is nothing short of an art form.”

You can find our hardware in the Smithsonian National Air and Space Museum!

RCT designs and manufactures propulsion systems for pioneering vehicles operated by leading aerospace startups, OEMs, and defense primes.

Our close-knit team designs and builds unique propellers and rotors for nearly every type of aerospace vehicle. We’ve supplied everything from 12” diameter variable pitch rotors for unconventional unmanned applications, to pusher fans that absorb thousands of horsepower.

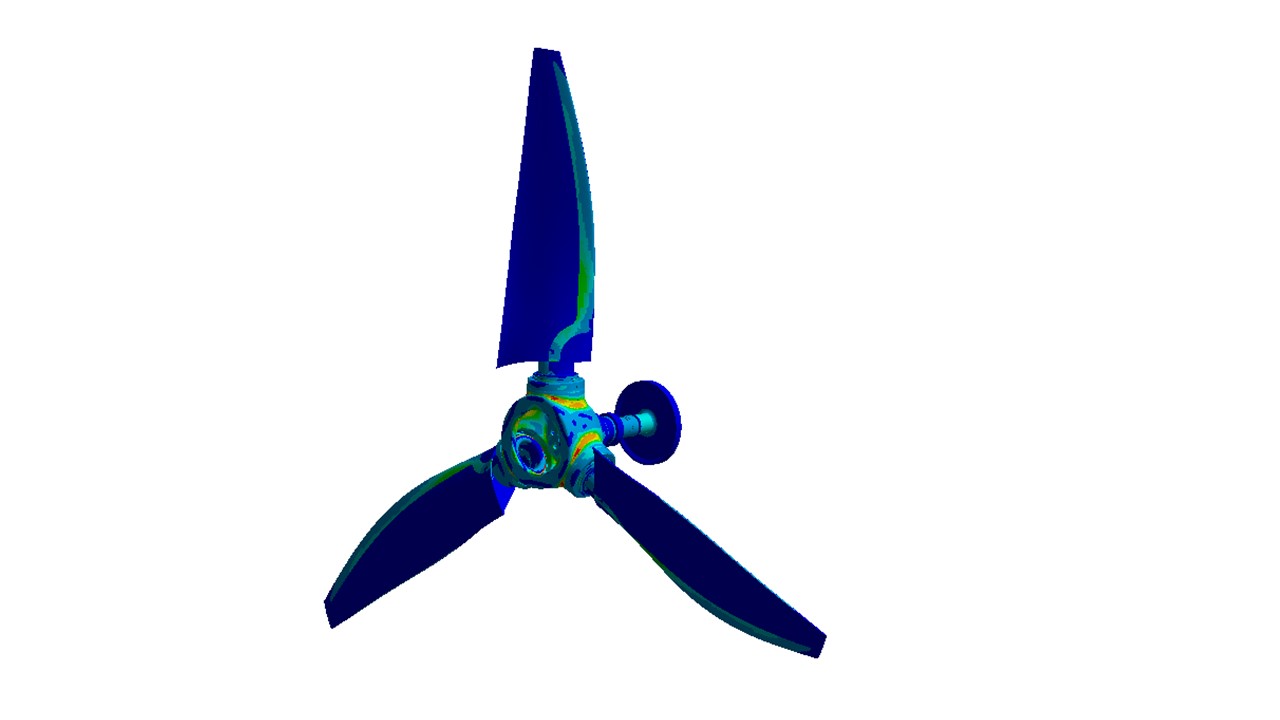

AERODYNAMIC & STRUCTURAL DESIGN

AERODYNAMIC & STRUCTURAL DESIGN

The projects are never the same, but we have the process down to a science. Projects begin with a customer’s mission requirements or existing aero loft shape. Utilizing a suite of industry proven and proprietary in-house tools, we then create a preliminary blade structural design, balancing the aerodynamic and structural requirements to ensure a safe and producible end product. Blade internal structure along with actuation and retention hardware draws on a deep FAA certification pedigree, and is sized to handle steady and vibratory loads. The blade structure is vibrationally tuned to avoid damaging resonance during operation. Complementing our in-house capabilities, RCT has a deep partner network that can provide expert acoustic predictions, 3D aero simulations, or test support.

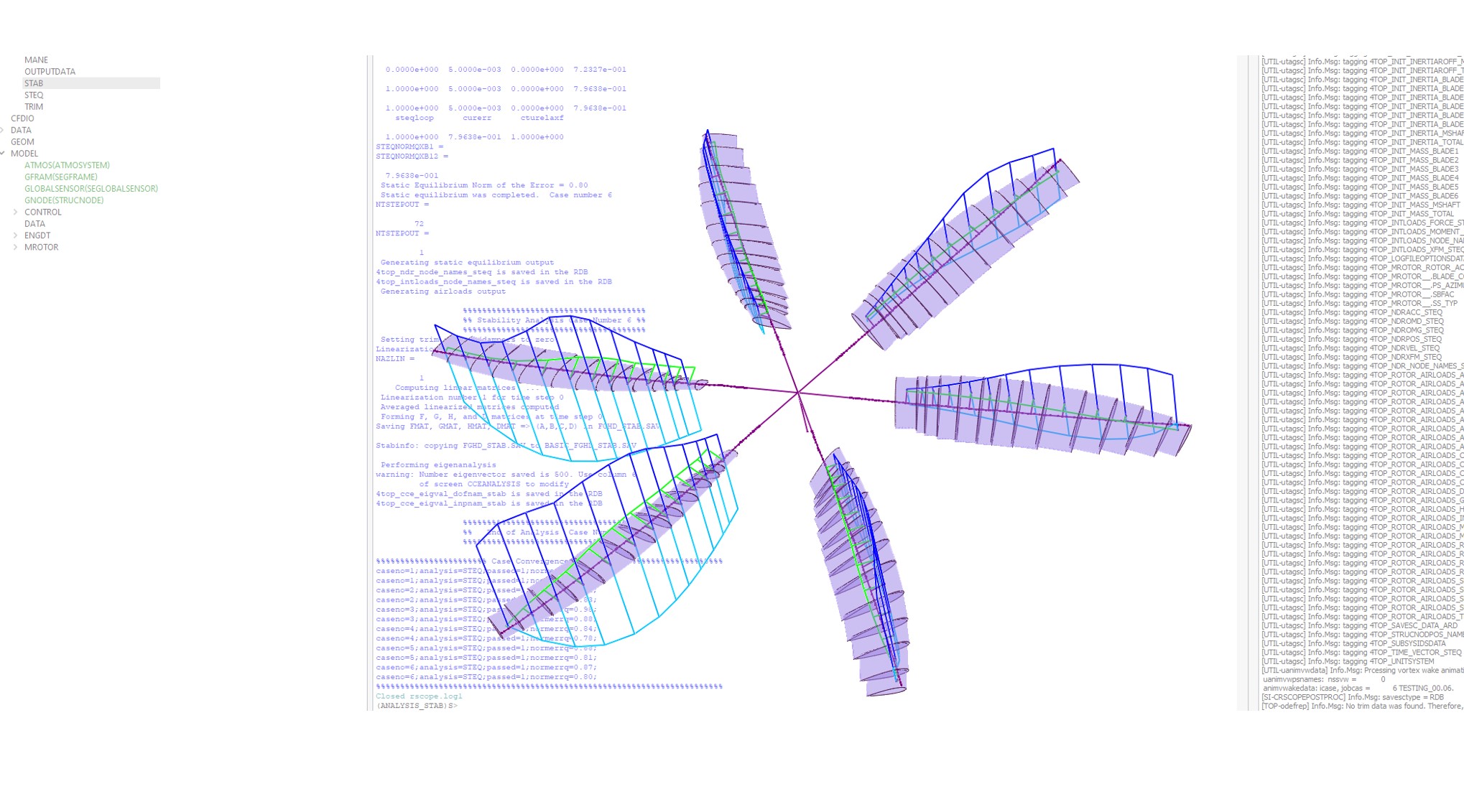

ANALYSIS & SIMULATION

ANALYSIS & SIMULATION

RCT’s engineers have trained with the experts. Our experience saves your program team time and effort, allowing you to utilize your resources in the most efficient and cost-effective way possible. We use some of the most sophisticated tools in the industry like RCAS, VABS, and ANSYS. This information is supplemented with dependable in-house design and analysis codes, all of which put each design through its paces early in the development process. RCT engineers love what they do, and it shows.

PROTOTYPING & MANUFACTURING

PROTOTYPING & MANUFACTURING

From design concept to flight hardware, RCT specializes in the entire end-to-end process of producing Resin Transfer Molded (“RTM”) composite blade assemblies. Our manufacturing capabilities include

-

- Ply cutting and kitting

- Spar and blade layup

- Blade molding

- Oven cure

- Test Design

We have a strong network of domestic suppliers dedicated to supporting additional special process and fabrication needs. Our experienced team knows how to squeeze time from a development schedule while minimizing program risk. From material selection to mold design, you can trust RCT to deliver solid hardware.

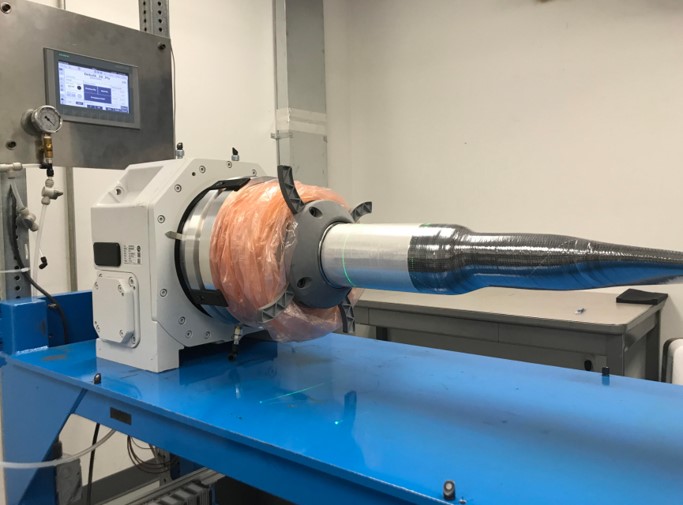

ASSEMBLY & BENCH TEST

ASSEMBLY & BENCH TEST

VEHICLE INTEGRATION SUPPORT

VEHICLE INTEGRATION SUPPORT

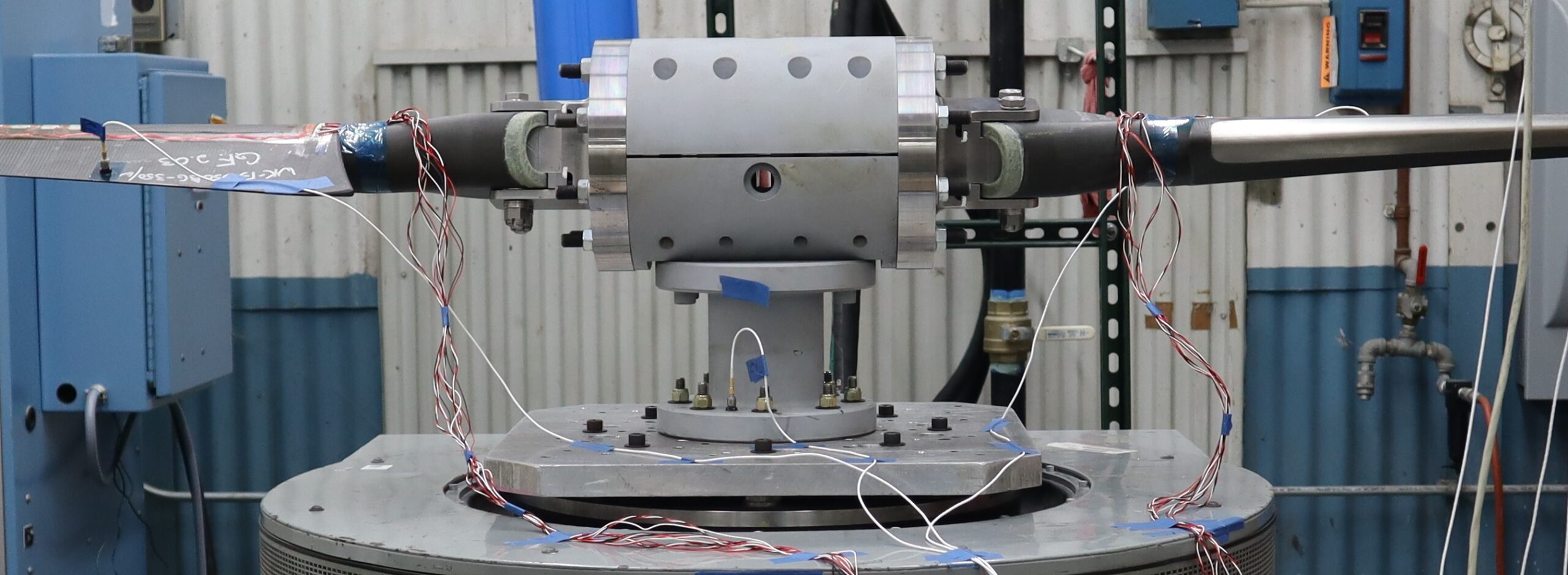

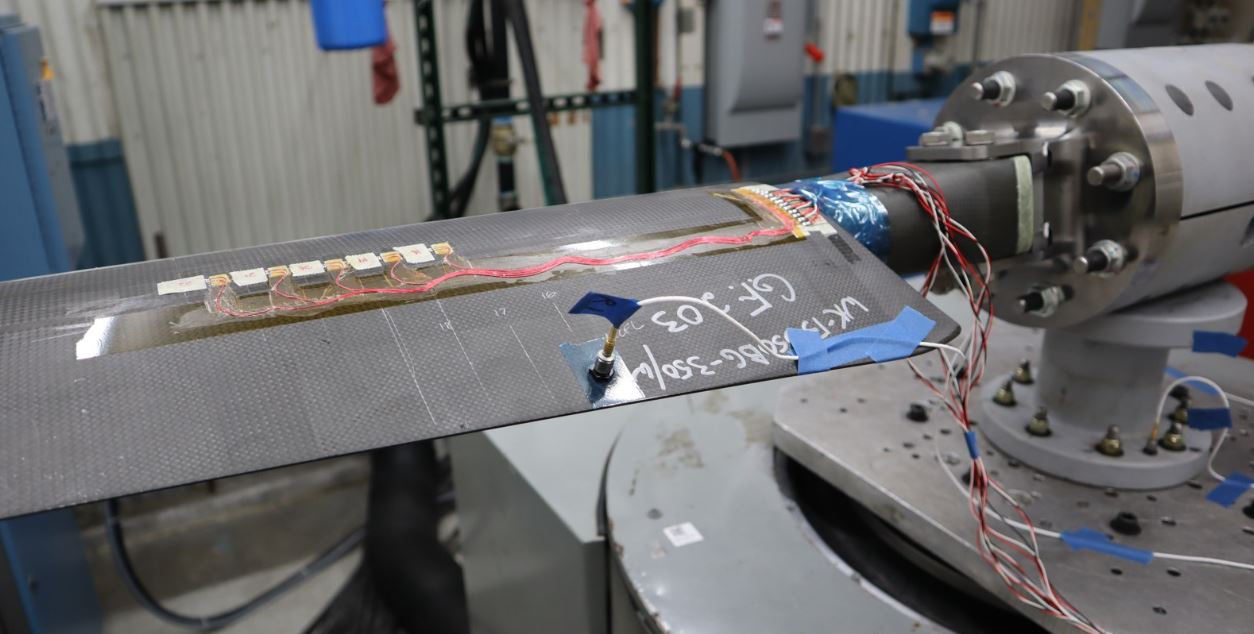

RCT staff have worked flight testing with defense and aerospace OEM customers for years. Our long track record of successful equipment deployments means we can design a test campaign to meet your needs. We can architect and author test plans and reports, support hardware installation and rigging, and support on-site vehicle integration. A 32-channel high-speed wireless data acquisition system designed and built by RCT allows operational strain and other measurements to be recorded on rotating hardware during actual flight conditions. Contact us to see how a customized solution can take your project to the next level.

REGULATORY COMPLIANCE

REGULATORY COMPLIANCE

-

- Lightning Strike

- Bird Strike

- Hub and Blade Fatigue

- Ground & Flight Strain Surveys

- Composite Material Qualification

- Spin Testing, Hydraulic Proof

- Burst Testing

If this is your first rodeo, trust us: you do not want to go it alone.